Energy efficiency technologies have drastically reduced GHG emissions in commercial buildings within the built environment. However, by considering other initiatives, companies can develop a more robust approach for their Net Zero plans to reduce GHG emissions in commercial buildings.

With population growth and urbanization continuing to increase, the environmental footprint of commercial buildings is gaining scrutiny now and will likely continue. Within the US, businesses and government agencies own, operate, and use 93 billion square feet of real estate, consume 3.98 petawatt hours of electricity (representing 35% of all electricity consumed in the US), and generate 826 million metric tons of CO2 emissions (16% of US total), according to the Department of Energy’s Commercial Buildings Integration Program. These emissions are the byproduct of energy consumed for heating, ventilation, and air conditioning (HVAC), cooking, lighting, appliances, and plug loads. On average, 30% of the energy used in commercial buildings is wasted, according to the Environmental Protection Agency.

Innovation and growth in energy efficiency technologies have served us well. Such initiatives have helped avoid the expansion of power plants, decreased electricity usage, lowered utility bills, and reduced emissions. In the spirit of Marie Kondo, we say, “thank you for your service” and we anticipate developments in energy efficiency will continue to provide technological breakthroughs that generate additional emission reductions and cost savings.

However, sustainability strategies for commercial spaces extend beyond just energy efficiency initiatives. They include (1) integrating sources of renewable energy, (2) natural gas to electricity conversion, and (3) improved insulation. Incorporating these additional approaches enables more comprehensive Net Zero plans to achieve sustainability goals and meet stakeholder demands. In addition, these initiatives meet the “business case” criteria for investment by delivering a positive ROI for the company. Let’s dive into these strategies.

Strategy #1: Integrating Sources of Renewable Energy

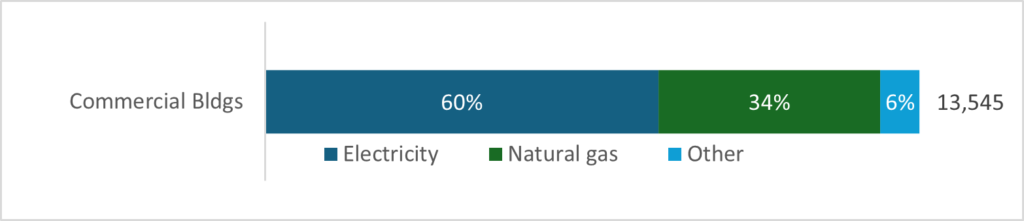

According to the 2018 Commercial Buildings Energy Consumption Survey (CBECS) conducted by the Energy Information Administration (EIA), electricity accounted for 60% and natural gas accounted for 34% of total energy usage in US commercial buildings. Opportunities for GHG emissions reduction can be found in both renewable energy sources and conversion from natural gas to electricity.

Commercial Building Energy Consumption by Fuel Type (trillions of BTUs)

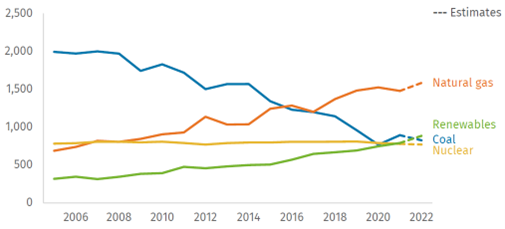

Natural gas is currently the primary fuel source for generating electricity followed by renewables, coal, and nuclear. With significant price drops, solar and wind have grown substantially in recent years.

US Power Generation by Energy Source: 2006-2022 (billions of kWh)

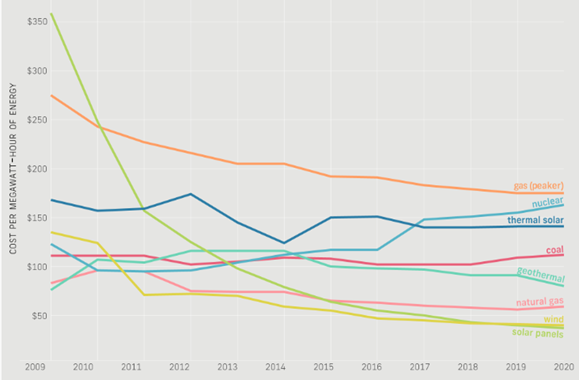

In 2018, $141 billion was spent on energy, with 84% spend on electricity ($119 billion) and 12% on natural gas ($16 billion), according to CBECS. Assuming current levelized cost of energy (LCOE) estimates from Lazard (version 16.0) of $77/MWh for natural gas, $140/MWh for coal, $72/MWh for utility solar, and $57/MWh for onshore wind, converting all electricity generated by natural gas (39% of generated electricity) and coal (20% of generated electricity) to onshore wind and solar would net a savings of approximately $22.8 billion.

Levelized Cost of Energy by Generation Source

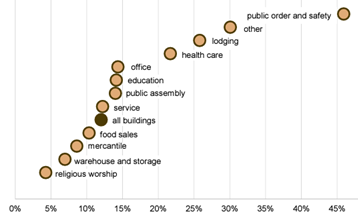

Availability and cost of renewable sources of energy will differ by region. In cases where there is limited supply to transition to clean energy, companies can explore options to generate their own sources of electricity through investments in solar, wind, or geothermal. Currently only 5% to 15% of most building types generate their own electricity, indicating opportunities to invest in additional renewable energy sources on-site.

Electricity Generation in Commercial Buildings

Strategy #2: Natural Gas to Electricity Conversion

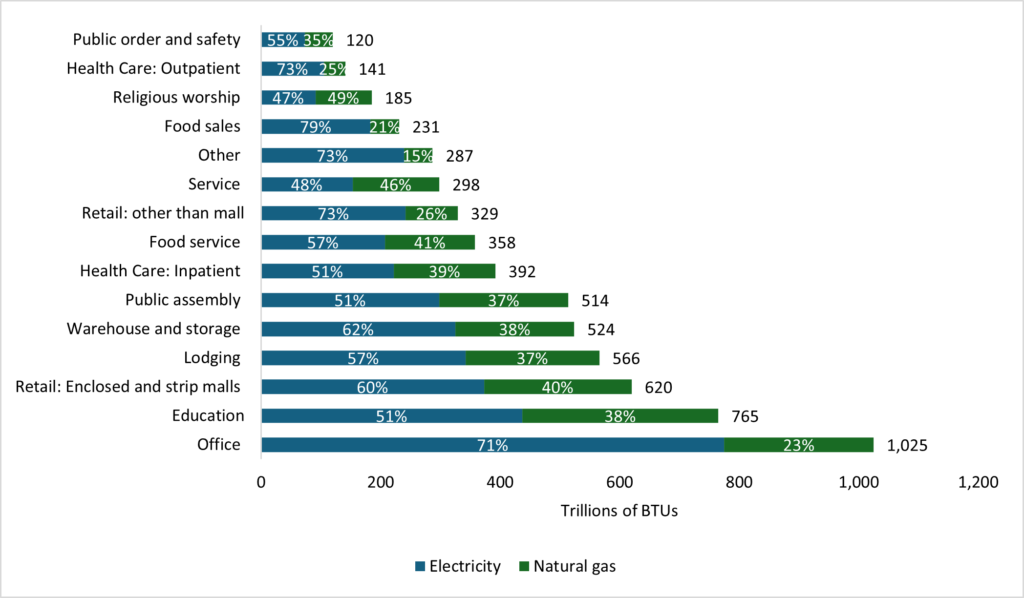

As previously mentioned, roughly 34% of energy consumed by commercial buildings comes from natural gas. As shown in the chart below, the mix of electricity versus natural gas usage varies by building type, with natural gas consumption ranging from a low of 25% (outpatient healthcare) to a high of 49% (religious worship). The highest consumption of overall energy is concentrated in office buildings which uses 1.03 quadrillion British thermal units (BTUs), representing 16% of all energy consumption across commercial buildings.

Commercial Building Energy Consumption by Fuel Type and Building Type (trillions of BTUs)

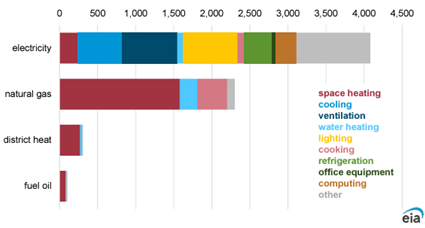

Most natural gas in buildings is used for space heating, cooking, and water heating as shown below.

Energy Consumption by Major Fuel and End Use (in trillions of BTUs)

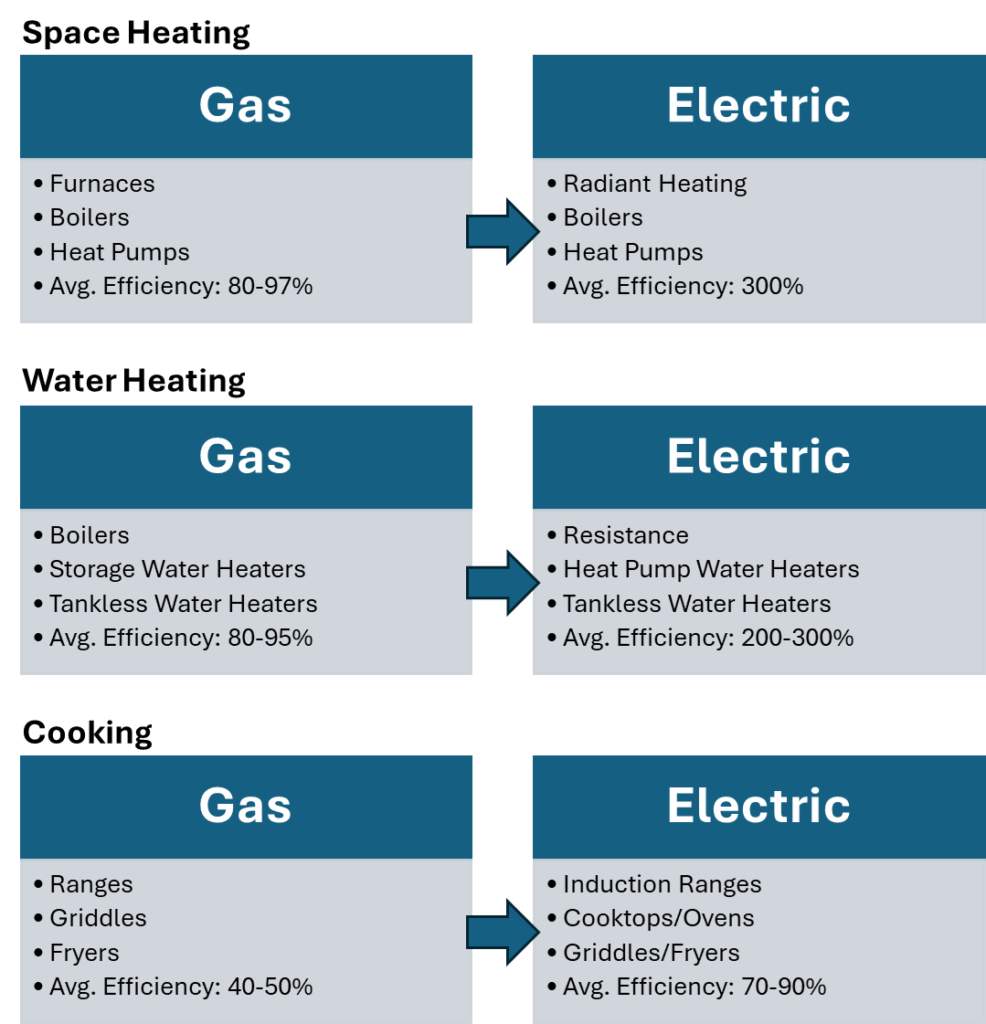

Accordingly, these primary categories of natural gas consumption are prime candidates for conversion to electric alternatives.

While electricity tends to be more expensive than natural gas ($25 to $30 versus $8.50 to $10.00 per MMBTU), the higher efficiency for electric technologies, especially heat pumps and induction cooktops, can offset some of the cost differences. Therefore, it is important to compare the total cost of ownership (TCO) including any available incentives for purchasing electric technologies when evaluating investment decisions.

Strategy #3: Improved insulation

Insulation may not garner a lot of attention in the energy efficiency discussion; however, it is a relevant driver to reduce electricity and natural gas consumption, resulting in lower emissions. High quality and adequate insulation boosts heat retention and loss during the summer and winter. Common types of insulation include fiber glass (affordable and effective), cellulose (an eco-friendly option made from recycled paper), foam board (high thermal resistance), and spray foam (excellent air sealing properties). Recent innovations in insulation include aerogel, known for its exceptional insulating properties with minimal thickness, and phase change materials (PCMs), which absorb and release thermal energy during phase transitions to regulate temperature fluctuations.

A study conducted by ICF found that upgrading building envelope insulation leads to substantial energy savings and carbon emissions. Specific highlights include:

Industrial Facilities

- Pipe and mechanical insulation improvements to industrial facilities in eight major industrial sectors can save more than $126 billion in energy costs (based on an average capital cost of $3.77 billion)

- The average payback on this investment is about 1 year; for many industrial sectors, the payback is as little as 6 months

Commercial Buildings

Over a 30-year period, upgrading roof insulation on existing commercial buildings can:

- Save building owners more than $65 billion in energy costs

- Eliminate nearly 338 million metric tons of CO2e emission savings, equivalent to the emissions of 2.4 million gas-powered cars or 30 years of emissions from three coal-fired plants.

Summary and Conclusion

Energy efficiency technologies have made significant strides in reducing GHG emissions in commercial buildings, but to create a more comprehensive Net Zero plan, companies must also consider integrating renewable energy sources, converting natural gas technologies to electricity, and improving insulation. With the growing environmental footprint of commercial buildings due to population growth and urbanization, it is essential to adopt a multifaceted approach to sustainability. These strategies not only contribute to reducing emissions but also offer a positive return on investment, making them a smart choice for businesses looking to meet stakeholder demands and achieve their sustainability goals. For guidance on navigating these strategies for your portfolio of sustainability initiatives or Net Zero plans, please contact Canopy Edge.