The Carbon Border Adjustment Mechanism (CBAM) is a carbon tariff on carbon intensive products, such as steel, cement and some electricity, imported to the European Union (EU). The goal is to reduce carbon emissions, prevent EU companies from relocating their operations due to competitive pressures, and encourage other countries to adopt similar carbon pricing mechanisms. CBAM will initially apply to the import of iron, steel, aluminum, hydrogen, electricity, cement, and fertilizer. Eventually, CBAM will cover all sectors included by the EU Emissions Trading System (EU ETS) by 2030.

In its transitional phase, compliance with CBAM will require companies to disclose their embedded emissions from imported goods on a quarterly basis. Beginning in 2026, companies must buy carbon certificates corresponding to the carbon price that would have been due if the goods had been produced under the EU’s carbon pricing rules. When fully implemented, CBAM certificates must be surrendered on an annual basis. To offset the initial cost of the CBAM for importers, there will be the availability of “free allowances”. Under the current EU ETS, producers benefit from such allowances with a carbon price paid on emissions only once the allowances have been considered.

Impact on Supply Chains

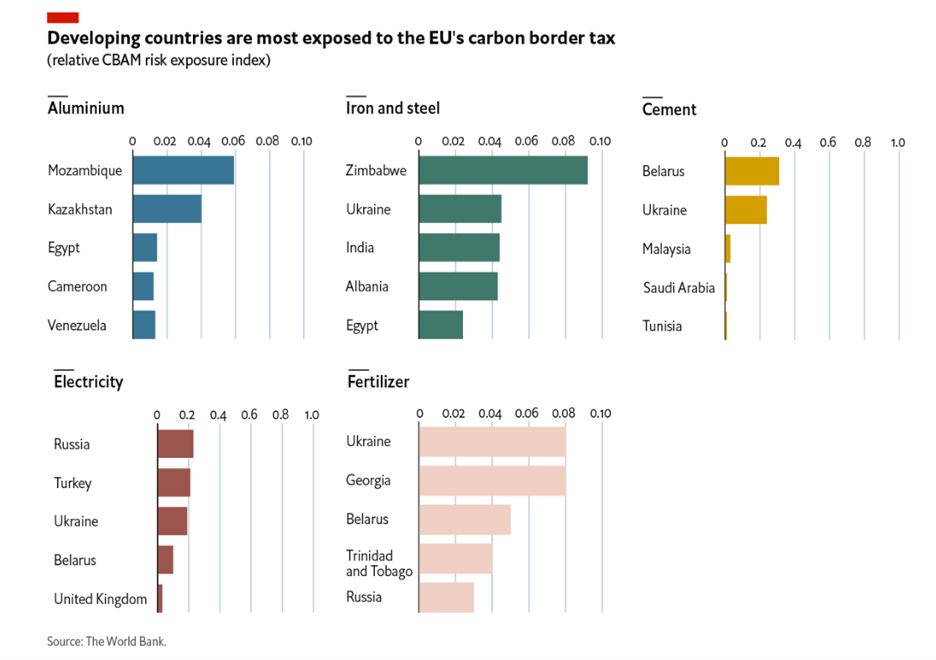

CBAM will impact global supply chains in different ways. For instance, high-carbon producers outside the EU will become less competitive in the EU market when the price of carbon is included in their exports. End users in the EU are likely to face higher prices, and may start to look for alternative trading partners or require existing trading partners to reduce the carbon content of their products. Multinationals may need to reconsider their offshoring and sourcing strategies in the light of the changing dynamics.

The levies can be significant. For example, Spain imported 14.5 million tons of steel in 2022, half of which came from outside the EU. Assuming an average carbon intensity of steel and the current EU carbon price, Spanish steel importers could face annual tariffs of some €1 billion when CBAM regulations are fully enforced in 2034.

Importance of Supply Chain Traceability for CBAM Compliance

Supply chain traceability is crucial for CBAM compliance because it allows importers to:

- Accurately calculate embedded emissions: By tracking the production process from raw materials extraction to final product delivery, importers can determine the carbon footprint of each stage and calculate the total emissions associated with the imported goods.

- Identify emission hotspots: Helps identify specific stages in the supply chain where emissions are particularly high, enabling companies to target their decarbonization efforts effectively.

- Verify supplier claims: Verifies the accuracy of emissions data provided by suppliers, ensuring that they are not paying for certificates that do not correspond to the actual carbon footprint of the imported goods.

- Demonstrate compliance: Provides evidence of CBAM compliance, helping importers avoid penalties and maintain market access in the EU.

In order to have supply chain traceability, companies need to establish systems to collect and manage data on emissions from suppliers, transportation, and other relevant stages of the supply chain. They will need to work closely with suppliers to ensure their cooperation in providing accurate emissions data and implementing sustainability measures. It will be important to adopt technology solutions, such as blockchain or digital platforms, to streamline data collection, verification, and reporting. And finally, regularly review and update traceability processes to adapt to changing regulations and industry best practices. By investing in supply chain traceability, companies can mitigate the risks associated with CBAM compliance, improve their environmental performance, and gain a competitive advantage in the global market.

Prepare Your Supply Chain for the Future

By complying with CBAM, companies can significantly improve the resilience and sustainability of their supply chains, thereby mitigating risks and positioning themselves for long-term success. CBAM is not the only regulation focused on sustainability. You may already be taking steps to comply with regulations in other jurisdictions. For CBAM, it is important to do the following:

- Risk assessment and mitigation: Conduct a thorough assessment of your supply chain to identify potential risks, such as reliance on single suppliers, geographic concentration, or exposure to natural disasters. Develop contingency plans to address risks, including alternative sourcing options, disaster recovery procedures, and insurance coverage.

- Supply chain visibility: Implement tracking systems for the movement of goods and materials throughout your supply chain, providing real-time visibility into potential disruptions.

- Geographic diversification: Source materials and components from different regions to reduce exposure to localized risks.

- Technology adoption: Utilize data analytics, implement automation technologies, and explore the potential of blockchain technology. Blockchain can enhance transparency, traceability, and security within your supply chain.

- Environmental impact: Consider the environmental footprint of your supply chain and implement sustainable practices.

- Build flexibility: Design your supply chain to be adaptable to changing conditions, allowing you to quickly adjust to unforeseen challenges.

Supply Chain Sustainability Initiatives

These companies, along with others, have made commitments to achieve supply chain sustainability. This gives them an advantage in complying with CBAM.

Nike has set a goal of achieving net zero emissions across its entire business, including its supply chain, by 2050. The company is focusing on reducing emissions from their operations, sourcing sustainable materials, and investing in renewable energy. Nike’s Global Operations and Logistics team has developed the Supply Chain Sustainability Index (SCSI), which sets clear and consistent minimum sustainability requirements for logistics service providers who do business with us and drives innovation discussions

Apple has set a goal to shift all electricity used throughout its supply chain to renewable sources by 2030. This is a multi-part strategy to achieve carbon neutrality across its entire business by 2030. Transitioning energy used in its supply chain to renewables is a key part of Apple’s strategy, alongside planned investments in the development of low-carbon product designs and nature-based carbon removal solutions. The majority of Apple’s carbon footprint originates from its global manufacturing partners.

In conclusion, CBAM is a significant policy development with opportunities and challenges for global supply chains. Companies need to carefully assess its implications, adapt their strategies, and invest in sustainable practices to navigate the evolving landscape.

To find out more about getting started on supply chain traceability for CBAM compliance, contact Canopy Edge for an assessment of how we can quickly launch a highly effective and efficient program to make meaningful sustainability progress within your supply chain.