The industrial sector accounts for more than 30% of global greenhouse gas (GHG) emissions, and nearly 40% of global energy consumption. This makes it the second largest emitter after power generation. However, the demand for energy and industrial products is anticipated to increase tremendously. Without an emissions reduction effort within the industrial sector, the goal of limiting global temperature rise to 1.5 Celsius above pre-industrial levels is likely unreachable. This is why industrial decarbonization has become a critical focus in the global sustainability conversation.

The industrial sector is a major contributor to GHG emissions, especially carbon dioxide (CO2). Industries such as steel, cement, chemicals, and food production rely heavily on fossil fuels for energy and raw materials. These emissions contribute significantly to global warming, leading to climate change-related challenges like rising sea levels, extreme weather events, and biodiversity loss.

According to the European Union’s (EU) Copernicus Climate Change Service (C3S), this year is “virtually certain” to surpass 2023 as the world’s warmest since records began. The data was released ahead of the UN COP29 climate summit in Azerbaijan, where countries will attempt to agree on a huge increase in funding to tackle climate change. Scientists anticipate that 2024 will be the first year in which the planet is more than 1.5°C hotter than in the 1850-1900 pre-industrial period, when humans began burning fossil fuels on an industrial scale.

Many companies have set ambitious goals to help reduce carbon emissions as they have begun to recognize that decarbonization could potentially help them generate higher revenue, improve profit margins, and lower costs.

Key Strategies for Industrial Decarbonization

Industrial decarbonization is a complex challenge, but companies, governments and the public recognize how crucial it is for mitigating climate change. Here are some key strategies to achieve this goal:

- Energy efficiency: Improving the efficiency of appliances, buildings, and industrial processes significantly reduces the amount of energy needed to perform the same tasks. This directly translates to lower emissions from power plants and other energy sources. There is less reliance on fossil fuels like coal, oil, and natural gas, which are major contributors to GHG emissions. Energy-efficient systems are better equipped to handle and integrate renewable energy sources like solar and wind power, allowing for a smoother transition to a cleaner energy mix.

- Electrification: By transitioning to electric vehicles (EVs), heat pumps, and electricity-powered industrial processes, we can significantly reduce direct emissions. This also allows us to harness clean energy sources like solar, wind, and hydro power more effectively. It is important to note that the effectiveness of electrification depends on the cleanliness of the electricity generation mix, and efforts to decarbonize the power grid are crucial. While initial investments may be higher, the long-term benefits of electrification in terms of reduced emissions and a more sustainable future are substantial.

- Low-carbon fuels: Low-carbon fuels, like biofuels, hydrogen, and synthetic fuels, play a vital role in decarbonization. These fuels are produced using processes that capture or reduce carbon emissions, resulting in a lower overall carbon footprint compared to traditional fossil fuels. They also contribute to cleaner air by producing fewer harmful pollutants, such as nitrogen oxides and particulate matter.

- Carbon Capture, Utilization, and Storage (CCUS): CCUS is a powerful tool for reducing industrial emissions. It involves capturing CO2 from industrial processes, leveraging it for various purposes, or storing it underground to prevent its release into the atmosphere. The captured CO2 can then be used in several ways, such as enhancing oil recovery, producing chemicals, or creating building materials. Alternatively, it can be compressed and injected deep underground into suitable geological formations for long-term storage. CCUS offers several advantages for industrial decarbonization as it can significantly reduce emissions from hard-to-abate sectors like steel, cement, and chemicals. However, CCUS also faces challenges as the technology is currently expensive, and the energy-intensive capture and storage processes can increase overall emissions.

Case Studies

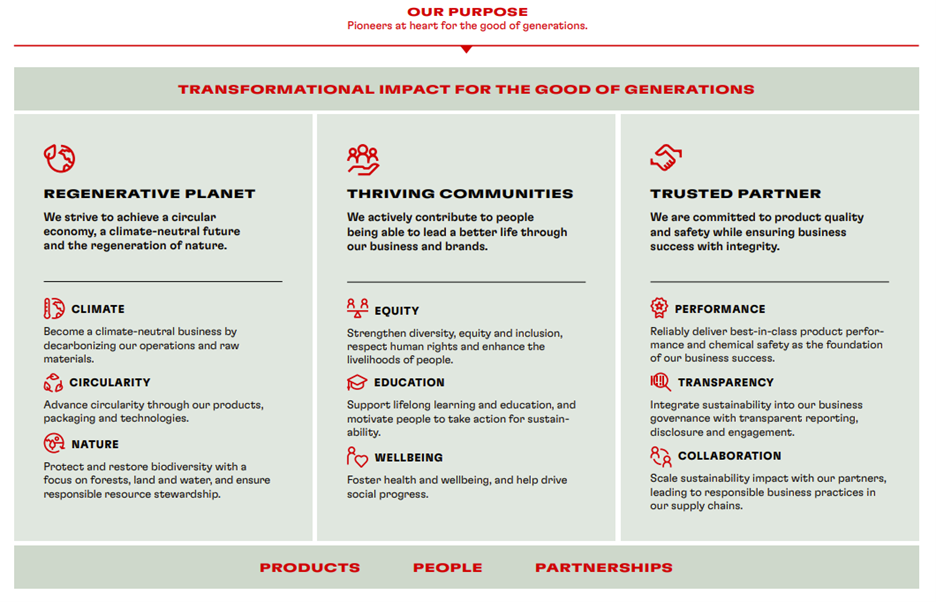

Henkel, a global adhesives and consumer brands manufacturer, aims to reduce its environmental impact and improve resource efficiency. In order to accomplish this goal, the company has implemented a series of sustainability initiativesthat include:

- Improve energy efficiency in production processes

- Reduce water consumption

- Increase the use of recycled materials

- Develop sustainable packaging solutions

By the end of 2023, Henkel fully converted 19 of its worldwide facilities to run on renewable electricity sources. The company achieved this through on-site energy production, which includes wind and solar, as well as direct purchasing of green power from local utility companies. In addition, Henkel entered virtual power purchase agreements (VPPAs) through which it buys renewable energy credits, serving to decarbonize geographically diffuse operations. As a result, Henkel has achieved significant reductions in energy consumption, water usage, and GHG emissions.

Kellogg Company

The Kellogg Company has set lofty science-based targets to reduce its GHG emissions across its value chain. Kellogg is focused on reducing emissions from its operations, supply chain, and product formulations. The company has made significant progress in reducing its carbon footprint, which includes switching to renewable energy sources and optimizing its supply chain. As of 2022, its accomplishments include:

- 31.1% absolute reduction in Scope 1 and 2 GHG emissions (since 2015)

- 13% absolutely reduction in Scope 3 GHG emissions (since 2015, as of December 2021)

- 40.3% of electricity used was from renewable sources (in 2022)

- 17% reduction in water use in high stress regions (since 2015)

- 23% reduction in food waste (since 2016, as of December 2021)

- 76% of packaging is recyclable at scale (in 2021)

To summarize, industrial decarbonization is a critical component of global sustainability efforts. The industrial sector makes a significant contribution to GHG emissions, underscoring the urgent need for decarbonization strategies to mitigate climate change and ensure a sustainable future. By implementing energy efficiency measures, electrifying processes, utilizing low-carbon fuels, and employing carbon capture, utilization, and storage technologies, industries can significantly reduce their carbon footprint. Companies like Henkel and Kellogg demonstrate the potential for substantial progress through proactive sustainability initiatives.