Climate change, as a pressing global threat, underscores the need for companies to adopt sustainable practices that help them identify and overcome challenges stemming from environmental factors. According to an IBM Institute for Business Value Survey, 62% of consumers are willing to alter their purchasing behavior to minimize environmental impact. Sustainable practices can lead to reduced energy consumption, lower waste disposal costs, and more efficient use of resources, resulting in significant cost savings. They can also drive innovation, leading to the development of new, eco-friendly products and services that can capture new market segments. In addition, sustainable practices can provide access to capital and investment as many investors prioritize environmental factors when making investment decisions. Companies with strong sustainability records are often more attractive to investors, and may be eligible for government incentives, grants, and green loans, providing access to additional funding.

Environmental Impact of Global Supply Chains

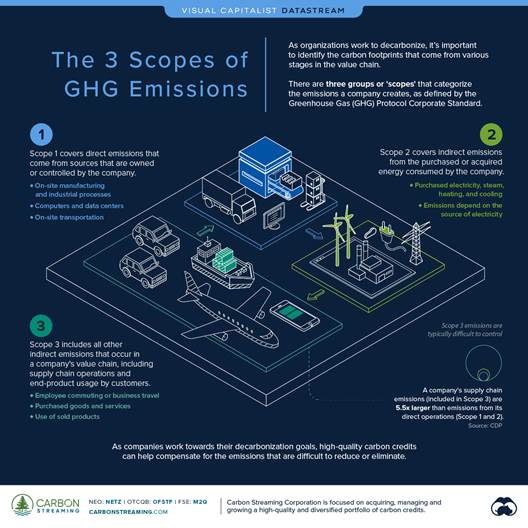

Global supply chains are responsible for over 90% of a company’s environmental impact, according to the CDP (formerly the Carbon Disclosure Project), including emissions from raw materials extraction, manufacturing, transportation, and end-of-life disposal. This is because each step of the supply chain, from sourcing to manufacturing, transportation, distribution, and disposal, contributes to the overall environmental footprint. For example, long-distance transportation, often by air or sea, generates significant greenhouse gas (GHG) emissions. In addition, manufacturing processes consume vast amounts of energy and raw materials, which can lead to deforestation, water pollution, and resource depletion. Finally, at every stage, waste is produced, including manufacturing waste, packaging waste, and electronic waste.

Sustainable Supply Chain Case Studies

Danone, a leading global food and beverage company, has a strong focus on sustainable supply chains. The company aims to minimize packaging and increase the reusability, recyclability, and compostability of packaging materials. Danone is working toward a “circular economy of packaging” by reducing the amount of packaging used, promoting recycling initiatives, and exploring innovative packaging solutions. In addition, Danone supports sustainable agricultural practices throughout its supply chain, including promoting regenerative agriculture, reducing the environmental impact of farming, and ensuring the well-being of farmers and their communities.

Adidas, a global athletic shoe and apparel company, has made significant strides in creating a more sustainable supply chain. The company has been a leader in using recycled polyester in its products, setting ambitious targets to replace virgin polyester with recycled options wherever possible. Adidas utilizes technology like TrusTrace to track materials throughout the supply chain, ensuring transparency and responsible sourcing. The company is constantly exploring and implementing innovative materials, such as Mylo (a leather alternative made from mycelium), to minimize environmental impact. Finally, Adidas is committed to reducing its carbon emissions across its entire value chain, from raw materials sourcing to product distribution.

Interface, the modular carpet tile manufacturer and parent company of FLOR, has made sustainability a core part of its overall business strategy, an achievement recognized by the 2020 UN Global Climate Action Award. The company utilizes 75% of the energy used at its manufacturing sites from renewable sources, including 100% renewable electricity at all factory locations. Furthermore, 76% of the energy consumed at its owned manufacturing facilities originates from renewable sources, resulting in a 96% reduction in market-based GHG emissions at its carpet manufacturing sites. Fifty percent of all materials incorporated into Interface’s flooring products are either recycled or bio-based. The company has also established a closed-loop recycling system that effectively transforms used carpet tiles into new products. This innovative approach has not only minimized waste but also significantly reduced the company’s reliance on non-renewable resources.

Regulatory Landscape for Supply Chain Sustainability

Companies are facing increased regulatory scrutiny for supply chain sustainability, leading to a surge in legislative action. The EU has been a pioneer in enacting stringent regulations related to supply chain sustainability, such as the Corporate Sustainability Due Diligence Directive (CSDDD). The CSDDD mandates that companies identify, assess, and mitigate adverse human rights and environmental impacts within their operations and throughout their supply chains. This legislation aims to increase transparency, drive systemic change, and ensure companies are held accountable for their social and environmental impacts. Similar legislation is emerging globally, reflecting a growing worldwide trend towards greater corporate accountability.

The EU’s Carbon Border Adjustment Mechanism (CBAM) is another key policy instrument designed to encourage sustainable supply chains. CBAM represents a significant policy development with the potential to drive substantial changes in global supply chains. To comply with CBAM, companies are required to track and report on the carbon emissions embedded in their imported goods throughout the entire supply chain, necessitating greater transparency and collaboration with their suppliers. More than a dozen other countries around the world are considering implementing their own CBAMs, which would move this framework closer to being a standard for global trade.

State-Level Regulations in the US

California SB 253 requires companies with over $1 billion in annual revenue operating in California to report both direct (Scopes 1 and 2) and indirect (Scope 3) emissions. California has strict regulations on emissions, renewable energy, and waste management, which significantly impact supply chains

New York introduced the Climate Leadership and Community Protection Act which aims to achieve a carbon-neutral economy by 2050 and requires significant reductions in GHG emissions. New York also has regulations related to emissions disclosure and renewable energy procurement.

Unfortunately, the patchwork of state-level regulations can create challenges for businesses operating in multiple states. Also, state-level regulations are constantly evolving, so it is crucial for businesses to stay informed about the latest developments.

Conclusion

Modern supply chains are often complex and multi-tiered, making it challenging to track and monitor sustainability performance across the entire value chain. Sustainability standards and best practices are constantly evolving, requiring companies to continuously adapt and improve their practices to stay ahead. These factors combine to create a complex and dynamic regulatory landscape for supply chain sustainability. Companies that fail to adapt to these changing regulations risk facing significant legal and reputational consequences.

Companies focused on addressing their Scope 3 supply chain emissions will find a strategic partner in Canopy Edge. Our firm offers customizable services for Scope 3 GHG footprinting and supplier engagement and understands the complexities and challenges associated with managing indirect emissions across extensive supply chains, including best practices for navigating compliance frameworks such as CSDDD, CBAM, and state-level requirements. Canopy Edge can accelerate your progress toward sustainability by offering strategic advice, practical solutions, and ongoing support.